iFluor® 440 succinimidyl ester

AAT Bioquest's iFluor® dyes are optimized for labeling proteins, particularly antibodies. These dyes are bright, photostable, and have minimal quenching on proteins. They can be well excited by the major laser lines of fluorescence instruments (e.g., 350, 405, 488, 555, and 633 nm). iFluor® 440 dyes are designed to be a superior replacement for DEAC dye that has extremely poor water solubility. iFluor® 440 SE is reasonably stable and shows good reactivity and selectivity with protein amino groups. Under the same conditions, iFluor® 440 dye conjugates are significantly brighter than the corresponding bioconjugates of DEAC or other spectrally similar dyes (such as SpectrumAqua), making the iFluor® 440 conjugates much more sensitive.

| Catalog | Size | Price | Quantity |

|---|---|---|---|

| 1041 | 1 mg | Price | |

| 71041 | 100 ug | Price | |

| 71519 | 5 mg | Price | |

| 71569 | 10 mg | Price |

Physical properties

| Molecular weight | 692.83 |

| Solvent | DMSO |

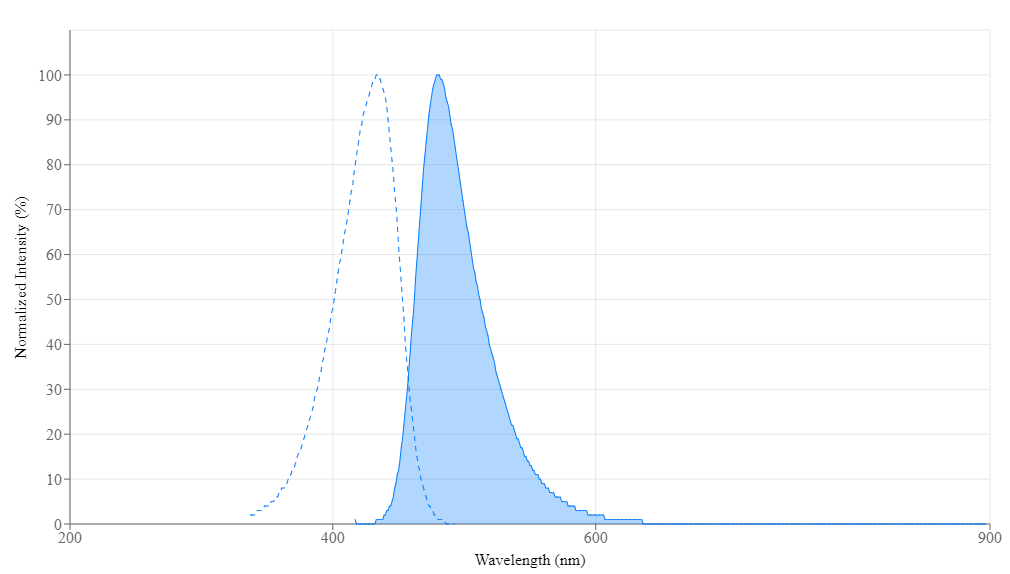

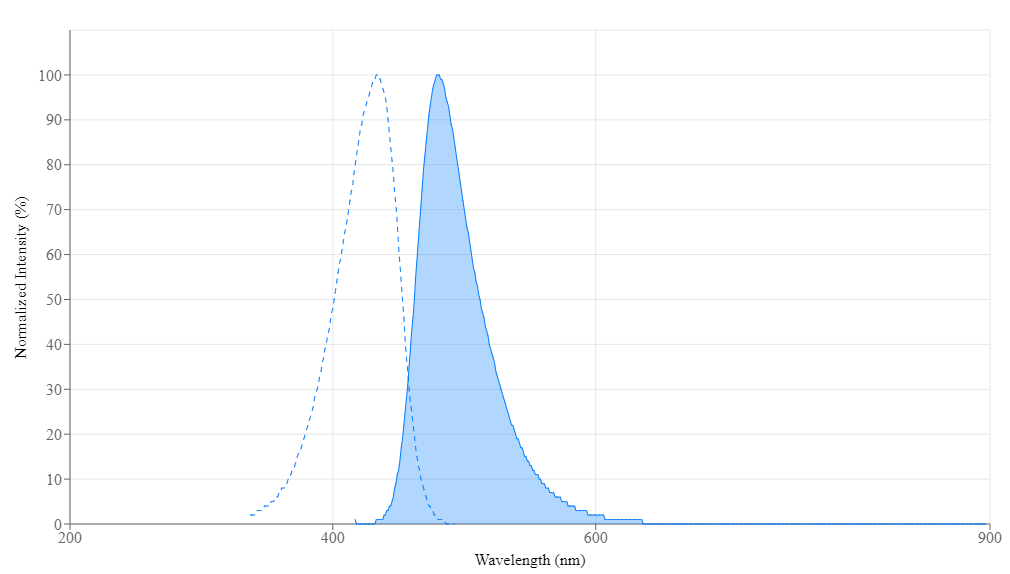

Spectral properties

| Absorbance (nm) | 430 |

| Correction factor (260 nm) | 0.352 |

| Correction factor (280 nm) | 0.229 |

| Extinction coefficient (cm -1 M -1) | 40000 1 |

| Excitation (nm) | 434 |

| Emission (nm) | 480 |

| Quantum yield | 0.67 1 |

Storage, safety and handling

| H-phrase | H303, H313, H333 |

| Hazard symbol | XN |

| Intended use | Research Use Only (RUO) |

| R-phrase | R20, R21, R22 |

| Storage | Freeze (< -15 °C); Minimize light exposure |

| UNSPSC | 12171501 |

Contact us

| Telephone | |

| Fax | |

| sales@aatbio.com | |

| International | See distributors |

| Bulk request | Inquire |

| Custom size | Inquire |

| Technical Support | Contact us |

| Request quotation | Request |

| Purchase order | Send to sales@aatbio.com |

| Shipping | Standard overnight for United States, inquire for international |

Page updated on January 22, 2026